For Tanker, Chemical Tanker and LPG & LNG Cargo Vessel, Vessel Uses LNG As Fuel

XT-USSL-ESD-T is universal link emergency shutdown system developed by Xtronica AS to comply with the requirement/recommendation of Oil Companies International Marine Forum (OCIMF) set for Linked Ship/shore Emergency Shutdown Systems for oil and chemical transfer. XT-USSL-ESD-T can be installed on Tanker, Chemical Tanker and LPG vessel for emergency shutdown control during oil and chemical transferring.

XT-USSL-ESD-T used same architecture as Xtronica As’s DNV and CCS type approved Remote Valve Control and Tank Level Gauging & Alarming System IECEx Certificate which have proven performance and high reliability for long history application in marine and offshore oil&gas industry. XT-USSL-ESD-T adopts Xtronica AS’s latest innovative 4th generation IoT based technology of application logic controller(ALC) and

X-SCADA control system achieving high level automatic and intelligent control.

XT-USSL-ESD-N is universal ship/ship, ship/shore link emergency shutdown system developed by Xtronica AS to comply with the requirement/recommendation of IGC/IGF code, SIGTTO and SGMF set for Linked Ship/shore Emergency Shutdown Systems for LNG transfer. XT-USSL-ESD-N can be installed on LNG Cargo Vessel and Ship uses LNG as fuel for emergency shutdown control during LNG transferring.

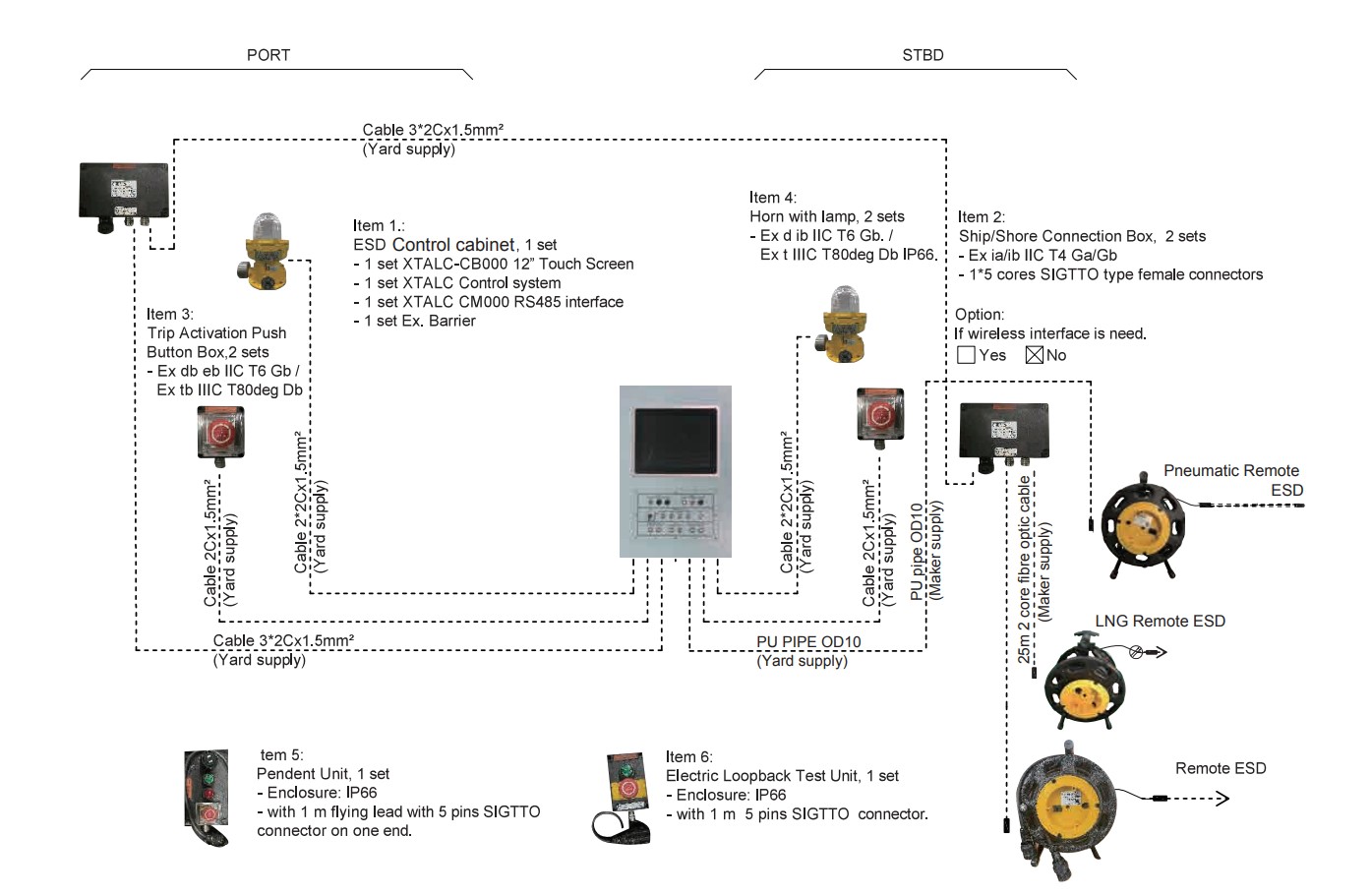

By supporting various connection interface including but not limited to pneumatic pipe, SIGTTO 5 way twisted electric cable, 37 way electric cable, 2 core fiber optic cable, 6 core fiber optic cable and wireless umbilical link, XT-USSL-ESD-T/N accomplishes single operator to monitor and control both sides of the transfer process to ensure that the measurements remain within safe criteria and shut down the process automatically and safely without risk of damaging surge pressures should these criteria be exceeded with maximum compatibility with other parties system.

Specifically XT-USSL-ESD-N achieves followings:

- The bunkering safety link has bi-directional and compatible signal interface and any activation of the emergency shutdown is actioned simultaneously on both the gas fueled vessel and the bunkering facility;

- The system is of fail-safe design;

- Manually activation of own ESD, automatically activate/trip other party’s ESD system and vice versa;

- The ESD should be tripped automatically if any of the recommended initiators as listed in Activation Items of Functions List;

- Can be de-energized during connection;

- Health situation is clearly indicated when it is connected with other party’s system for the condition of electrical power (air supply for pneumatic systems) and circuitry fault status;

- The electrical classification, IP rating and etc. of the system are suitable for the working environment;

- Raises an audible and visual alarm when ESD is activated;

- The system can be tested both is linked and independently;

- Hot line phone connection and data exchange are available via 37 way electric cable as well as 6 cores and 2 cores fiber optic cable connection.